Production of biochar

For more than two thousand years, charcoal and biochar have been one of civilisation's basic materials. Use the European Biochar Certificate (EBC) for the production of biochar and its processing and use.

The EBC guarantees that the biomass feedstock is sustainably procured and produced, emissions limits are adhered to and storage procedures are environmentally sound. All aspects of the biochar’s quality are monitored and documented, and all the limits for the various usage classes (agriculture, materials, other) are complied with in accordance with the applicable regulations. The certified biochar can be used – among other things – as a soil improver, as litter (bedding) material, as an additive in fermentation substrates, for effluent treatment, and as an additive in construction materials, plastics, paper, textiles and storage batteries.

Benefit to customer

Biochar that is produced in accordance with the standards of the European Biochar Certificate (EBC) meets all the requirements of sustainable production with a positive climate and environmental footprint. EBC certification demonstrates that your biochar complies with the applicable requirements for protection of the environment, users and soils. Certification guarantees that the biochar used in agriculture is safe and environmentally sustainable.

Here you will find the current version of our standard:

Related documents:

187

customers are certified with the European Biochar Certificate

64'000

tons of certified EBC biochar in 2023.

The current certificates for all businesses can be viewed here.

Registration Process

After an initial call with one of Carbon Standards‘ team members (which can be scheduled here), the next step is to register your interest in beginning the certification process.

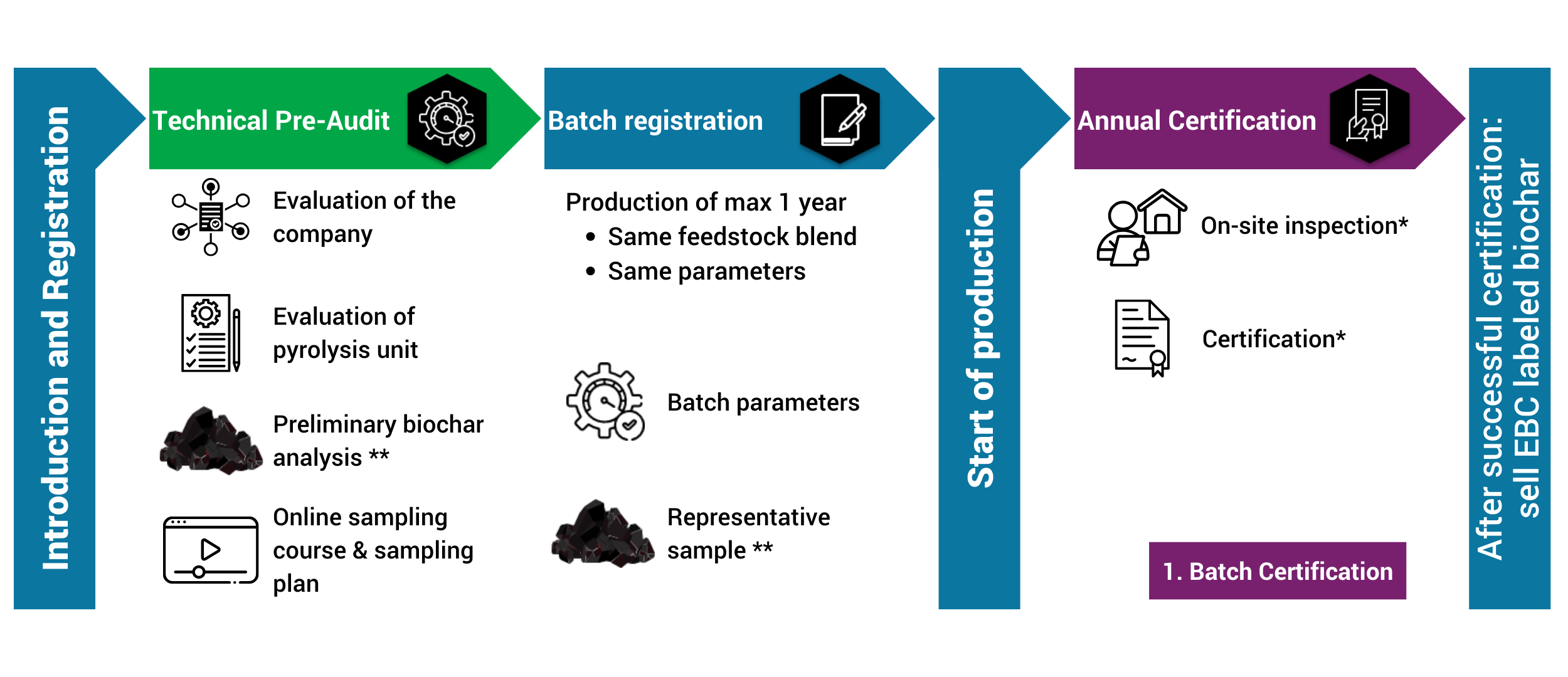

Certification process

The Certification Process involves a Technical Pre-Audit of the biochar production company including material process flows and emissions, a review of the pyrolysis technology and the resulting biochar as well as a review of the production company’s sampling plan. Following a successful pre-audit, companies may register their first-year production batch. A third-party on-site inspection is the final step in the certification process. Once all steps have been successfully completed, the sale of EBC-certified biochar can begin.

* By inspection and certification partner

** Analyzed by – Endorsed laboratory

Technical Pre-Audit

In the technical pre-audit, Carbon Standards will review the pyrolysis technology against the specifications in the guidelines and, if necessary, offer advice on improving the biochar production process. Carbon Standards also checks whether the EBC guidelines for the sustainable production of biochar have been thoroughly understood by the biochar producer with all necessary processes in place to implement them.

Representative Sample

Producers must take a representative sample for each batch and have it tested in an endorsed laboratory.

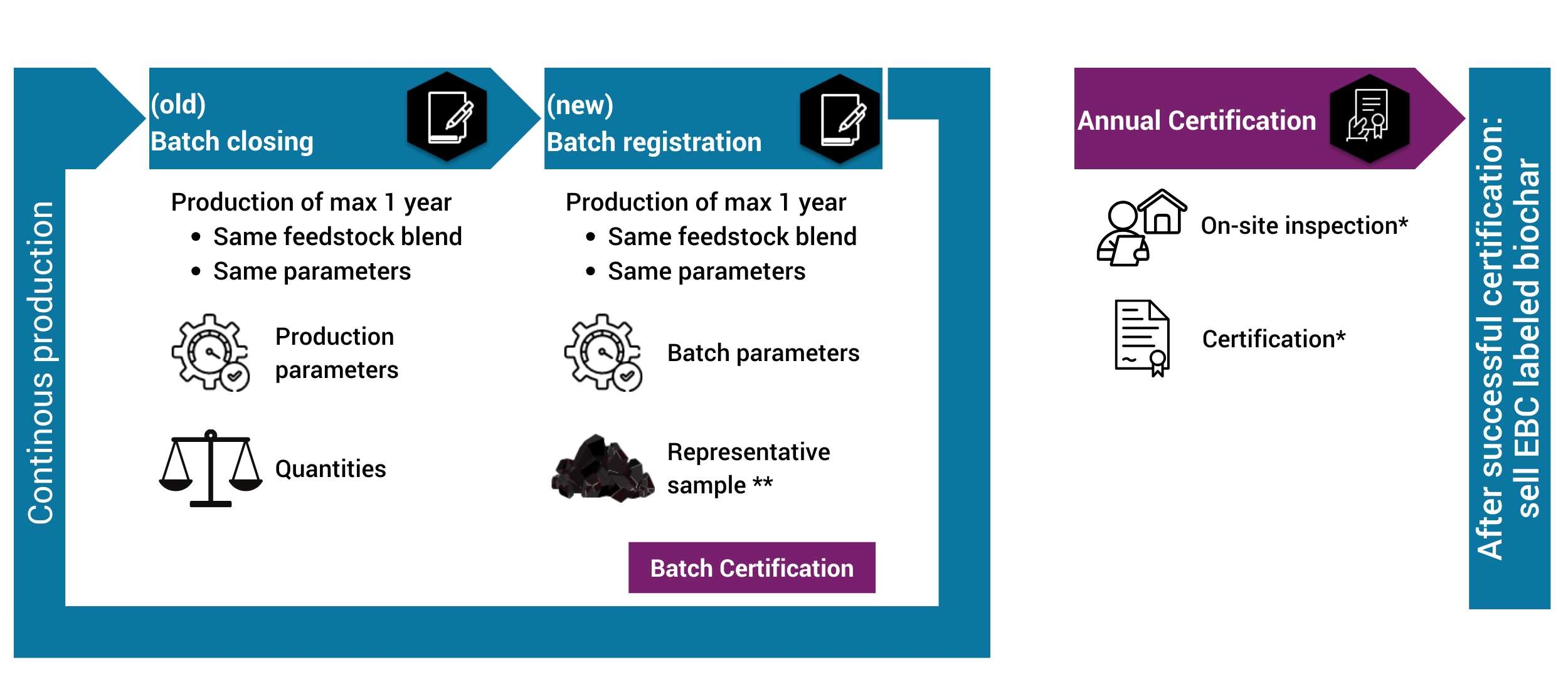

On-going Production

Biochar production batches are valid and certified for up to one year. Producers will be required to register new production batches of biochar made from the same feedstock and processing parameters annually. Each new batch will require new biochar samples to be analyzed before they can be certified. New batches will also be required when new feedstocks or feedstock mixes or new processing parameters (e.g. heating temperatures) are utilized.

An on-site inspection is carried out every year.

* By inspection and certification partner

** Analyzed by – Endorsed laboratory

This document explains how producers initiate new production batches using Carbon Standard’s Biochar Tool (and for legacy clients the EBC Tool).

All endorsed laboratories and subcontractors take part in an independent biochar ring trial every year, which is organized and evaluated by DCC Delta Coal Control. Our goal is to set up an international network of laboratories for biochar analysis that work using the same analysis methods and regularly take part in the biochar ring trial testing to ensure accurate and consistent results across all endorsed facilities.

For testing laboratories interested in becoming endorsed by Carbon Standards, please review the following documents:

This document outlines the steps required to participate in a 3rd party controlled ring trial to become an endorsed laboratory for certifying biochar under the EBC/WBC standards.

This document should be used to request biochar reference samples (#1017) to begin the ring trial process. (Note: Dates on the form are related to the annual testing period.) New labs will be sent reference materials upon request and payment of the invoice.

A list of currently endorsed laboratories can be found below.

Eurofins Oekometric GmbH

Bernecker Strasse

D-95448 Bayreuth

Germany

Tel: +49 921 72633 - 0

E-mail: rottler(at)oekometric.de

Eurofins Umwelt Ost GmbH

Freiberg Branch

Freiberg East industrial estate

Lindenstraße 11

D-09627 Bobritzsch-Hilbersdorf

Germany

Phone: +49 3731 2076 - 500

Mobile: +49 172 9224436

E-mail: info_freiberg(at)eurofins.de

mas | münster analytical solutions gmbh

Technology Park Münster

Wilhelm-Schickard-Strasse 5

D-48149 Münster

Germany

Tel.:+49 251 384415-12

E-Mail: contact(at)mas-tp.com

Ruhr Lab GmbH

Laboratory at KW Scholven

Glückaufstrasse 56

D-45896 Gelsenkirchen

Germany

Phone: +49-152 268 760 15

E-mail: service(at)ruhr-lab.de

Find here a list of the System Providers endorsed so far:

Pyreg GmbH

The PYREG technology carbonises your waste materials into pollutant-free, highly porous biochar (plant carbon). In contrast to rotting or incineration, the carbon contained in the residues is not released as CO2 in this process, but is stably bound in the biochar and thus removed from the atmosphere.

This makes the production of biochar one of the Negative Emission Technologies (NET) urgently needed for climate protection. Because if this biochar is permanently incorporated into so-called carbon sinks (e.g. arable land, building materials, asphalt), the sustainable storage of CO2 is successful in the long term.

SynCraft Engineering GmbH

Wood in particular plays an important role in the energy generation of tomorrow. With SynCraft's wood-fired power plants, the renewable raw material can be optimally utilised. This self-developed and patented technology generates more electricity and heat - in addition, bioenergy is the only renewable energy that can be switched on and off as needed.

Endorsed System Providers can offer several benefits and advantages for new system buyers that want to get an EBC/WBC certification or C-sinks through EBC C-Sink or Global Biochar C-Sink standards including:

- The technical pre-audit is shorter and less expensive due to:

a) A preliminary lab analysis is not needed as the system has already proved to be capable of producing biochar according to EBC and WBC.

b) The preparation of the documents by the system provider shortens the work of the future biochar producer and the system provider can support him in the process. - Methane measurements for each individual production unit are not required. The default value per system is used to calculate the methane emissions of the pyrolysis unit.

- Assurance that technology has already qualified under EBC/WBC:

a) Investors confidence in carbon revenues may increase

b) Carbon buyers may have more confidence as well

EBC or WBC Certified biochar producers can utilize Carbon Standards’ Biochar Tool to manage all aspects of production including initiating and renewing batches, managing annual sample requirements and monitoring production volumes. The Biochar Tool can also be used during the technical pre-audit to share relevant documentation related to the pre-audit and certification process.

CERES-CERT AG

CERES-CERT AG is the third-party auditing body for the standards owned by Carbon Standards International.

With the experience in the certification of biochar, CERES-CERT AG has the necessary expertise to certify biochar production and processing companies and to validate and verify your climate projects.

If you would like to have Carbon Standards review potential modifications or amendments to the standard, please review the following:

Standard updates

Here you find old version of the standards including a marked version with the changes to the current version of the European Biochar Certificate.

The section provides relevant documents related to the general procedures, complaints & approval processes, and public consultation of projects.

Please refer to our Design Manual for the correct use of the label.

Contact person

Patrizia Pschera

Patrizia Pschera

Environment and Climate Specialist

+41 (0) 62 552 10 98

patrizia.pschera@carbon-standards.com

Alphons Puthiyidom

Alphons Puthiyidom

Environmental and Process Engineering Specialist

+41 (0) 62 552 10 94

alphons.puthiyidom@carbon-standards.com